byrongiffy

Supply Chain Management Today

More than ten years ago, a research study of 100+ manufacturers, distributors, and retailers uncovered some widely used supply chain strategies and initiatives. These ideas and practices were distilled down to seven principles and presented in an article in Supply Chain Management Review, a magazine widely read by SCM professionals.

Though they are more than a decade old, these timeless principles highlight the need for supply chain leaders to focus on the customer. They also stress the importance of coordinating activities (demand planning, sourcing, assembly, delivery, and information sharing) within and across organizations.

Supply chain management is essential to company success and customer satisfaction. Did you know that SCM also plays a critical role in society? It's absolutely true. SCM knowledge and capabilities can be used to support medical missions, conduct disaster relief operations, and handle other types of emergencies. SCM also plays a role in cultural evolution and helps improve our quality of life.

Whether dealing with day-to-day product flows or dealing with an unexpected natural disaster, supply chain experts roll up their sleeves and get busy. They diagnose problems, creatively work around disruptions, and figure out how to move essential products to people in need as efficiently as possible.

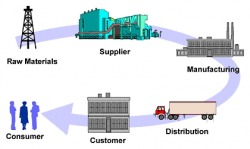

Details regarding the importance of SCM can be found by clicking on each hyperlink in the diagram.

(http://www.careersinsupplychain.org/what-is-scm/importance.asp)

Though they are more than a decade old, these timeless principles highlight the need for supply chain leaders to focus on the customer. They also stress the importance of coordinating activities (demand planning, sourcing, assembly, delivery, and information sharing) within and across organizations.

Supply chain management is essential to company success and customer satisfaction. Did you know that SCM also plays a critical role in society? It's absolutely true. SCM knowledge and capabilities can be used to support medical missions, conduct disaster relief operations, and handle other types of emergencies. SCM also plays a role in cultural evolution and helps improve our quality of life.

Whether dealing with day-to-day product flows or dealing with an unexpected natural disaster, supply chain experts roll up their sleeves and get busy. They diagnose problems, creatively work around disruptions, and figure out how to move essential products to people in need as efficiently as possible.

Details regarding the importance of SCM can be found by clicking on each hyperlink in the diagram.

(http://www.careersinsupplychain.org/what-is-scm/importance.asp)

Supply Chain Management Careers

First Level Management (0-4 years)

Demand Planner

Project ManagerVendor Managed Inventory (VMI) Analyst

Senior Consultant

Middle Level Management (5-10 years)

Master Production Scheduler

Sourcing ManagerDirector of Operations

Director of Transportation

Executive Level Management (11+ years)

Vice President of Global Logistics

(http://www.careersinsupplychain.org/job-roles-profiles/descript.asp)

Demand Planner

Project ManagerVendor Managed Inventory (VMI) Analyst

Senior Consultant

Middle Level Management (5-10 years)

Master Production Scheduler

Sourcing ManagerDirector of Operations

Director of Transportation

Executive Level Management (11+ years)

Vice President of Global Logistics

(http://www.careersinsupplychain.org/job-roles-profiles/descript.asp)

Supply Chain Management Mentor

Rich Cizmas -Owner and Operator of Hungry Howies Pizza, Las Vegas, NV

Marketplace

What are your projections for this type of work or industry?

This type of job is growing more and more important with the economy the way it is. Nobody wants to spend more money and resources than necessary, but things are becoming more computer based and there is less need for people to do the work.

What are the key trends or issues? New developments? Challenges?

At first when he opened his business, computers were not very prevalent, but eventually they computerized their store and got a point of sale system that electronically kept track of the inventories in and out of the store.

What and where are the opportunities?

Sales based companies and wholesalers.

Entry into Position

When and how did you get involved in this type of work?

In 1992 he decided that it was time to work his way up in life and he and his wife decided to get into a franchise. Pizza ended up being their game, so the bought into a system and the rest is history.

What was your training background? Is this typical for someone in your position?

He actually did not go to school specifically for supply chain, but he went to a 6 week training with the franchise to learn everything about managing, marketing and maintaining the company once he got started. This is probably not very typical where someone would go into this type of business without another kind of business background.

How important are specific credentials for entry or success?

The company does not want anyone to get into the business who is going to drive it into the ground and give them a bad name, so it is important to make a good impression to the franchise owners by performing well at the 6 week training.

Job Specifics

What is a typical day like for you?

He spends a lot of time at the computer. Its important to make a daily inventory of some items to keep theft down and it is also important for him to be there to make sure that the correct amounts of supplies are being used on each pizza. If the measurements are off a little bit then it could throw off his profit margin.

What do you like most about your work?

It was just a fun business to be in in general. He was sort of a celebrity in the neighborhood and he loved that. I think a lot of people dream about owning a pizza shop, and he actually did.

What do you like least?

Employees... It is tough to deal with dishonest or unmotivated employees.

What talents or skills are most necessary in this type of work?

Leadership is absolutely the most important thing in this type of business. If people do not trust and respect you, then you will get walked all over.

Who does not work well in this type of work?

Dishonest people.

Recommendations

Would my background be appropriate for this type of work?

Absolutely.

What would you recommend I do if I were to go into this type of work?

Depending on what level of supply chain you want to get into, college may or may not be important. For larger retail and wholesaling stores, college is a must.

Are there any jobs similar to yours that you would also suggest I consider?

Retailers, such as Wal-Mart, would be great places to look. They are some of the only places left that still need large-scale Supply Chain Management. Wholesale houses may also be a good place to look.

Knowing what you know now, would you approach this career in the same way?

He would not want to change anything. Everything that he did worked out as well as it could. He did set some goals that didn't take off like he hoped, but there were no bad mistakes that could have been avoided. Learn quickly who to order from and keep people honest by shopping around.

What are your projections for this type of work or industry?

This type of job is growing more and more important with the economy the way it is. Nobody wants to spend more money and resources than necessary, but things are becoming more computer based and there is less need for people to do the work.

What are the key trends or issues? New developments? Challenges?

At first when he opened his business, computers were not very prevalent, but eventually they computerized their store and got a point of sale system that electronically kept track of the inventories in and out of the store.

What and where are the opportunities?

Sales based companies and wholesalers.

Entry into Position

When and how did you get involved in this type of work?

In 1992 he decided that it was time to work his way up in life and he and his wife decided to get into a franchise. Pizza ended up being their game, so the bought into a system and the rest is history.

What was your training background? Is this typical for someone in your position?

He actually did not go to school specifically for supply chain, but he went to a 6 week training with the franchise to learn everything about managing, marketing and maintaining the company once he got started. This is probably not very typical where someone would go into this type of business without another kind of business background.

How important are specific credentials for entry or success?

The company does not want anyone to get into the business who is going to drive it into the ground and give them a bad name, so it is important to make a good impression to the franchise owners by performing well at the 6 week training.

Job Specifics

What is a typical day like for you?

He spends a lot of time at the computer. Its important to make a daily inventory of some items to keep theft down and it is also important for him to be there to make sure that the correct amounts of supplies are being used on each pizza. If the measurements are off a little bit then it could throw off his profit margin.

What do you like most about your work?

It was just a fun business to be in in general. He was sort of a celebrity in the neighborhood and he loved that. I think a lot of people dream about owning a pizza shop, and he actually did.

What do you like least?

Employees... It is tough to deal with dishonest or unmotivated employees.

What talents or skills are most necessary in this type of work?

Leadership is absolutely the most important thing in this type of business. If people do not trust and respect you, then you will get walked all over.

Who does not work well in this type of work?

Dishonest people.

Recommendations

Would my background be appropriate for this type of work?

Absolutely.

What would you recommend I do if I were to go into this type of work?

Depending on what level of supply chain you want to get into, college may or may not be important. For larger retail and wholesaling stores, college is a must.

Are there any jobs similar to yours that you would also suggest I consider?

Retailers, such as Wal-Mart, would be great places to look. They are some of the only places left that still need large-scale Supply Chain Management. Wholesale houses may also be a good place to look.

Knowing what you know now, would you approach this career in the same way?

He would not want to change anything. Everything that he did worked out as well as it could. He did set some goals that didn't take off like he hoped, but there were no bad mistakes that could have been avoided. Learn quickly who to order from and keep people honest by shopping around.

Supply Chain Management Key Terms

- Lead Time - the time interval between the start of an activity or process and its completion, for example, the time between ordering goods and their receipt, or between starting manufacturing of a product and its completion

- Cycle Time - the total time taken from the start of the production of a product or service to its completion. Cycle time includes processing time, move time, wait time, and inspection time, only the first of which creates value.

- JIT - just-in-time

- Lean Production - a methodology aimed at reducing waste in the form of overproduction, excessive lead time, or product defects in order to make a business more effective and more competitive. Lean production originates in the production systems established by Toyota in Japan in the 1950s. In the early 1980s there was a significant increase in the application of lean production in Western companies. Lean production is characterized by lean operations with low inventories, quality management through prevention of errors, small batch runs, just-in-time production, high commitment human resource policies, team-based working, and close relations with suppliers. The term was popularized by researchers on the International Motor Vehicle Program of the Massachusetts Institute of Technology in their book The Machine That Changed the World. Concepts that can help an organization move toward lean production include continuous improvement and world class manufacturing.

- SPC - statistical process control

- Six Sigma - a data-driven method for achieving near perfect quality. Sigma is the Greek letter used to denote standard deviation, or the measure of variation from the mean, which in production terms is used to imply a defect. The greater the number of sigmas, the fewer the defects. In true Six Sigma environments, companies operate at a quality level of six standard deviations from the mean, or at a defect level of 3.4 per million. Six Sigma analysis can be focused upon any part of production or service activities, and has a strong emphasis on statistical analysis in design, manufacturing, and customer-oriented activities. It is based on statistical tools and techniques of quality management developed by Joseph Juran. It was pioneered in the United States by Motorola, and subsequently became much more popular in the 1990s after its adoption by General Electric under Jack Welch.

- Logistics - the management of the movement, storage, and processing of materials and information in the supply chain. Logistics encompasses the acquisition of raw materials and components, manufacturing or processing, and the distribution of finished products to the end user. Each organization focuses on a different aspect of logistics, depending on its area of interest. For example, one might apply logistics to find a way of linking physical distribution management with earlier events in the supply chain, another to plan its acquisition and storage, while a third might use logistics as a support operation.

- Inventory Control - supervision of supply, storage and accessibility of items in order to insure an adequate supply without excessive oversupply.

- SKU - Stock Keeping Unit

- Level Loading - The term level load is one that applies to the annual fee, which is calculated and then deducted from a given mutual fund’s assets that belong to any specific investors. It will relate to those investments where there are relevant costs for such things as the distribution and marketing expenses. These will incur as long as the investor continues to have the funds. Such charges are paid to those who act as intermediaries for the selling of a fund’s shares. They will we involved any time the mutual funds are sold as retail to the public.

- RFID - Radio-frequency identification (RFID) is the use of an object (typically referred to as an RFID tag) applied to or incorporated into a product, animal, or person for the purpose of identification and tracking using radio waves. Some tags can be read from several meters away and beyond the line of sight of the reader.

(http://search.bnet.com/)